Infrastructure

Akar is fully equipped with the latest equipment to deliver quality, every time.

Laboratory

Sieve Analysis

Impact Testing Machine

Universal Testing Machine

Spectrometer

Salt Spray Chamber

Roughness Tester

Profile Projector

Nickel Thickness Tester

MPI Testing

Metallurgical Microscope

Design & Engineering

We use the latest Design Software, our Designing Department consists of a team of highly qualified Engineers, they follow a concept called NPD.

Heat Treatment Facility

All Units have in-house heat treatment facility –

Hand Tools Division is equipped with Shaker Hearth Furnace it is a Gas fired furnace with Polymer quenching having 5 Electric tempering Zone. It is used for Heat Treatment of all type of hand tools.

Forging Division is equipped with a Continus Pusher type SCAD Based Heat treatment plant which is capable for ISO Annealing, Normalizing, Harding and tempering of various forgings. Capacity of plant is around 22 metric ton per day.

Leaf Spring Division is equipped with Walking Beam type Fully automatic PLC control 12mt. German make Hardening Furnace with Oil Quenching With a capacity of 2500 metric ton and 15mt. Long Tempering Furnace, used for the heat treatment of Various Leaf springs.

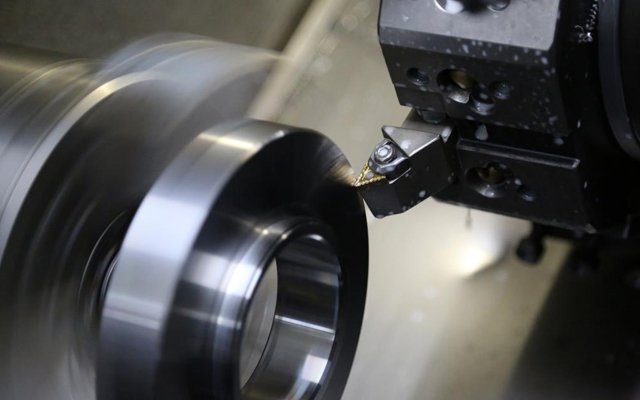

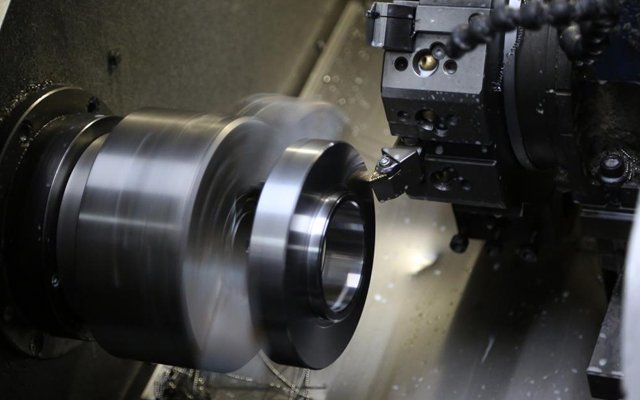

Tool Room

Akar is having fully equipped conventional and computerizes Tool Room, we make all the required Tooling at our Tool Room, it is having Surface grinder, EDM, CNC, Lathe Machine, milling, Shaper, Cutting, Drilling and a team of highly qualified and experience manpower.

We make all the required Tools and dies including brooches required by all the units of Akar

Forgings Capability

Akar is equipped with 2 forge shops,

6 drop forge hammers are installed at hand tools division, range from 0.75 tons to 1.5 tons, these are used for forging for various type of hand tools like wrenches, pliers, spanners etc.

3 drop forge hammers range from 0.75 ton to 3 ton are installed at Forging division.

We are having capability to forge any job from 0.03 Kg to 25 kg. All hammers at forging division are associated with electric furnaces to achieve scale free clean forgings, due to such capabilities Akar is number one supplier of lever Forgings to various Automotive Manufacturers.